ELECTRIC PROCESS HEATER

Over 100 years in development the advanced thermal technologies in industrial applications. Now, Chormalox is the best of manufacturer in the world providing the Industrial heater and control system.

Chromalox maintains six state-of-the-art manufacturing plants throughout the world with more than 634,000 ft2 of manufacturing space. The facilities are vertically integrated, and also provide final assembly and functional testing. Chromalox maintains numerous global product and plant certifications, including ISO 9001:2008, ATEX/IECEx, ASME, ATEX, PED, ABS, GOST, National Board, KOSHA, and SELO.

Chromalox also maintains a presence across the globe through our operations offices. These facilities provide design and engineering expertise, project management, sales, and service quickly, locally. Chromalox also stock and warehouse products and components for rapid delivery.

APPLICATION AND INDUSTRIES

|

Energy

|

Industrial

|

|

|

Commercial |

||

|

PROCESS ELECTRIC HEATER AND SYSTEM |

||

| XtremeDuty | ||

|

|

||

.jpg)

EX Process Electric Heater |

|

Heater EX'd' Control Pane |

ELECTRIC HEAT TRACING SYSTEM

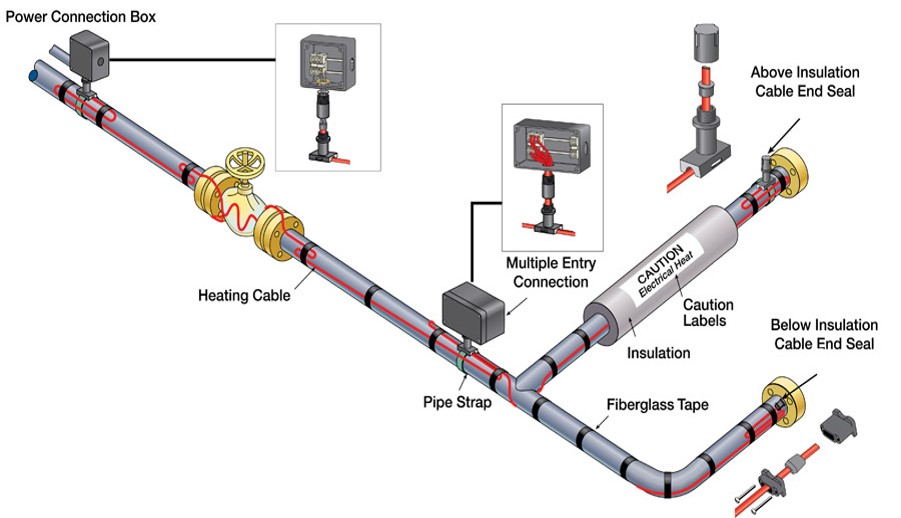

CHROMALOX Heat Trace Segment delivers Temperature Management Solutions for piping systems, valves, and tanks. Our Industrial Heat Trace and Systems Segment delivers for the right mix of application engineering, products and site services for their Process Temperature Maintenance, Freeze Protection, and Winterization needs and Process Heating Solutions for revenue-generating industrial processes.

APPLICATION AND INDUSTRIES

|

Energy

|

Industrial

|

|

|

|

Commercial |

|||

| HEAT TRACE COMPONENT AND CONTROL | |||

Heat Trace Field Components

|

Heat Trace Cable Chromalox heat trace cable includes cables for most process maintenance and pipe and vessel freeze protection, including: Self-regulating cable for ordinary and hazardous environments to prevent pipe freezing and maintain process temperatures up to 302°F/150°C, with maximum exposure temperature up to 420°F/215°C. Constant-wattage cable for freeze protection and process temperature maintenance up to 350°F/175°C, with maximum exposure temperature up to 392°F/200°C. Mineral-insulated cable for the most demanding heat trace applications, with temperature maintenance up to 900°F/480°C and maximum exposure temperature to 1,100°F/593°C. |

|

|

Digital Temperature Sensor The Chromalox DTS-HAZ digital temperature sensor is a microprocessor-based temperature control and monitoring unit for freeze protection or process maintenance of pipes or tanks protected by heat tracing products. Housed in a NEMA 4X enclosure, it includes terminals for connecting instrument power, heating cable, and RTD (remote temperature detector). It can be used with constant- wattage, mineral-insulated, or self-regulating heating cable in ordinary or Div. 2 hazardous area locations. |

|

Additional Features:

Heat Trace Controls

Chromalox Heat Trace Panels are complete control solutions for the most demanding heat trace applications.

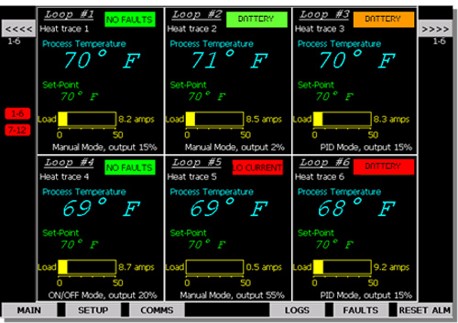

The intelliTRACE® ITLS (line sensing) and ITAS (ambient sensing) are microprocessor-based control/monitoring provides temperature control, monitoring and power management in one package. Choose from 1 to 72 circuit systems for either ambient or line sensing applications in ordinary or hazardous locations.

The intelliTRACE line offers advanced features such as sensor mapping, soft start, multiple sensor inputs per circuit and a large touch screen display. Choose the ISC Supervisory Controller to monitor and manage multiple intelliTRACE systems.

They feature a 10-inch touch-screen computer operator interface that provides real-time display of alarms for high/low temperatures, high/low current, ground fault leakage, and sensor faults.

|

and ITAS Control Panel |

|

.jpg)

IntelliTRACE Software |

IntelliTRACE 10-inch touch-screen |

Additional Features:

SCR control

Soft start

40 amp/loop at 100 to 480 VAC

6 to 36 loops, expandable to 72 loops

Full communications, wired and wireless

Enhanced data logging

NEMA 4 enclosure

Integral circuit panel with breaker

|

Skin-Effect Heat Trace System Chromalox skin-effect trace heating is ideal for the freeze protection, temperature maintenance, and heat-up of materials transported by long-distance pipelines (up to 15 miles/25 kilometers). Pipes can be above or below ground, submerged, and across all types of terrains. Skin-effect trace heating employs a single circuit, eliminating the need for an extensive power distribution system. This makes it an extremely cost-effective alternative to conventional trace heating, particularly in remote areas where installation and maintenance can be costly.

Applications: The movement of materials in tank farms.

The movement of materials in storage terminals.

Piping between distant processing facilities in the chemical, petrochemical, oil, and natural/refined gas industries.

Electrical Certification: Rated for voltages up to 3,000 V. Approvals • ATEX • GOST |

.jpg) |

HEAT TRACE SYSTEM DESIGN SOFTWARE

ChromaTrace is a Windows based heat tracing system design software. The straight forward interface allows the user to generate a bill of material, heatloss calculations and electrical loads quickly and accurately. Chromatrace performs the calculations and picks the appropriate Chromalox heat trace model, connection kits and temperature controls to satisfy the user’s unique application.

Chromatrace Features and Capabilities: